Pharmaceutical manufacturers face relentless pressure to protect their products, adhere to safety compliance, and, of course, keep costs down. A damaged shipment, a recall, or a quality issue can disrupt a supply chain and expose patients to risk. In 2025, pharmaceutical companies worldwide spent more than $103 billion on containers and protective packaging systems, underscoring the immense value of product protection and movement through manufacturing and logistics networks.

That scale highlights just how mission-critical packaging design has become for pharmaceutical logistics teams. Thermoformed plastic trays are the solution that can meet exacting specifications, reduce material waste, protect sensitive products, and streamline operations.

Thermoformed trays matter, and in this piece, we’ll cover both how they solve core manufacturing problems, and why custom plastic trays deserve a central place in your pharma packaging strategies.

Precision, Protection and Compliance in Pharma

Packaging in pharmaceutical manufacturing is strategic to supplying these products. Packaging must protect products from contamination and damage, meet strict regulatory standards, and integrate easily into high-speed, automated production lines. Custom plastic trays meet these demands by tailoring each tray to the product it holds. These trays’ precision designs promote safety and performance in ways stock trays simply can’t.

Custom thermoformed trays boost efficiency by minimizing empty space during shipping. They also help pharmaceutical companies maintain compliance by providing consistent, repeatable packaging that meets customer expectations.

The Unique Packaging Challenges to Pharmaceutical Manufacturing

Pharmaceutical manufacturing presents packaging experts with unique challenges that make generic trays inadequate.

Strict Regulatory and Compliance Requirements

Pharmaceutical packaging must satisfy rigorous standards such as FDA, cGMP, ISO, and USP. Manufacturers must document the materials used, validate their processes, and maintain traceability at every production stage. Packaging teams cannot compromise when regulatory scrutiny demands clear evidence of control and compliance.

Sensitivity of Pharmaceutical Products

Drugs and biologics often react to physical impact and contamination. A flawed packaging design can lead to compromised batches that fail quality checks or pose patient safety concerns.

High-Volume, High-Precision Production Environments

Today’s pharmaceutical lines rely on automation and rapid throughput. That means their product packaging must seamlessly integrate with robotics and material handling systems. Too much manual handling or poorly designed trays slow the line and increase human error.

What Makes Custom Plastic Trays Different?

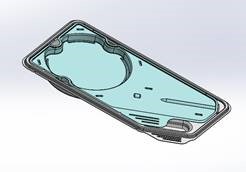

Unlike stock plastic trays, these custom tray solutions start with real line conditions. They account for specific product features, dimensions and tolerances while aligning with automation requirements.

In pharmaceutical environments, trays do more than hold parts. They control positioning and reduce movement as products move down the line to distribution. When trays match exact customer specifications, they function as part of the manufacturing system rather than an afterthought.

Definition and Core Functions

Custom plastic trays are thermoformed for a specific product profile. These trays secure items during transport, organize components on the shop floor, and support controlled environments from cleanrooms to distribution hubs.

Common Materials Used in Pharmaceutical Trays

Manufacturers can select materials like PETG, HIPS, PP, RPET, and other medical-grade plastics for their strength and consistency. Advanced customer design options include antistatic and ESD-safe plastics that meet their contamination control needs for highly specialized applications.

How Generic Trays Miss the Mark

Custom trays fit products exactly, reducing movement and damage risk for pharmaceutical customers. Generic trays assume that one design will serve many products, but this often leads to inefficiencies such as increased waste and higher long-term costs because products shift or sustain micro-damage during handling.

Benefits of Custom Plastic Trays in Pharmaceutical Manufacturing

Custom plastic trays deliver value to pharmaceutical customers by solving real operational problems. When these packaging solutions align with product requirements and fabrication conditions, they reduce risk and improve consistency on the floor. These benefits extend beyond protection to influence efficiency, quality outcomes, and long-term cost control.

Enhanced Product Protection and Stability

A cavity that holds each component tightly prevents shifting that can cause scratches, cracks, or contamination. The additional protection reduces rejects and recalls, strengthening the overall quality of the pharmaceutical customer's product.

Improved Cleanliness and Contamination Control

Customized cleanroom trays help maintain critical sanitary conditions. Reducing particulate generation during packaging and handling lowers the risk of product contamination and boosts the customer's environmental compliance.

Increased Manufacturing and Packaging Efficiency

Trays that fit products and equipment reduce manual effort on the packaging line. Faster loading and unloading improve cycle times. Finally, smoother integration with automation supports higher throughput, lowering labor and production costs.

Regulatory Compliance and Validation Support

Customized trays are repeatable. Designing for consistency simplifies your documentation and audit readiness because every tray conforms to the design that each customer validates during the tray development process.

Cost Savings Across the Product Lifecycle

Tailor-made trays lower expenses across factory operations and logistics by addressing these drivers at their source for our pharmaceutical customers. Better fit reduces scrap rates and limits the need for rework on the line. Consistency in tray geometry also improves shipping density, helping control transportation costs as your product volumes scale.

Custom Trays, Pharmaceutical Logistics and Distribution

The benefits of specialty packaging don’t end at the factory door. Specially designed trays can also contribute positively to pharmaceutical logistics, particularly when products travel through complex distribution networks.

Secure Transport of Drugs and Medical Components

Trays that cradle pharmaceutical products reduce shifting and damage during transit. This kind of stability protects sensitive drugs and components from vibration and impact consistently across the miles and multiple handoffs.

Stackability and Space Optimization

Trays that nest and stack efficiently save room in warehouses and shipping containers. More efficient use of volume cuts down on shipping expenses while reducing your packaging waste.

Tamper Resistance and Traceability

Custom-created trays support serialization and labeling, enhancing tracking across the entire supply chain. Tray geometry and surface design make it much easier to apply labels and maintain their readability throughout customer handling and transport workflows. This consistency undergirds traceability requirements while reducing the risk of mismatches or lost identifiers. For regulated products, stronger traceability improves security and simplifies reporting during audits and investigations.

Custom Plastic Trays for Medical Devices and Combination Products

Pharmaceutical manufacturers increasingly manage products that combine drugs with delivery devices or complex components. These products introduce additional packaging requirements that stock trays often cannot support.

Supporting Sterile and Non-Sterile Applications

Custom designed trays support both sterile and non-sterile applications depending on where they sit in the packaging workflow. For example, the primary packaging must protect product integrity throughout any pre-validated processes. Then, secondary packaging can provide additional protection during downstream handling and distribution.

Precision Cavities for Complex Geometries

Medical devices and combination products often include complex shapes that require precise positioning. Custom designed trays create repositories for holding syringes, vials, cartridges, inhalers, and device components securely throughout factory operations and distribution.

Compatibility With Sterilization Methods

The creation of specialized packaging materials can align with common sterilization processes such as gamma irradiation and ethylene oxide. In these environments, trays must maintain their dimensional stability and structural integrity through many cycles to protect the customer's product and its performance.

Sustainability Considerations in Pharmaceutical Tray Design

Environmental responsibility is a growing factor in pharmaceutical containment decisions. Manufacturers look for ways to reduce their material use without compromising the product’s integrity or compliance performance standards.

Lightweighting and Material Reduction

Specially created shipping trays allow manufacturers to remove unnecessary material while still preserving performance requirements. These companies engineer plastic thermoformed trays to securely support their products while using less plastic. Ultimately, they can reduce weight and lower their supply chain's transportation impact.

Thoughtful lightweighting also supports our customers’ expense control. When these units use materials efficiently, pharmaceutical companies often see savings in both material spend and freight costs without the need to change downstream processes.

Recyclable and Reusable Cost Effective Solutions

Thermoformed plastic trays made from materials such as RPET can support recycling initiatives when your handling and recovery conditions allow for it. In controlled environments, reusable shipping trays can also reduce corporate costs by circulating within defined internal workflows.

Both approaches rely on predictable handling conditions. Generally, recycling and reuse programs work best when products follow established movement patterns and their return paths remain consistent.

Balancing Sustainability With Regulatory Compliance

In pharmaceutical production, your environmental goals must align with regulatory expectations. Tray designs still need to meet validation requirements and maintain product integrity throughout their use.

For many applications, the perfect solution balances material efficiency with compliance. Custom thermoformed trays enable manufacturers to advance their environmental performance goals without introducing risk.

Designing the Right Custom Plastic Tray for Pharma Applications

Shipping trays for pharmaceutical use begin with an understanding of how the unit operates in the factory environment. Addressing these requirements early helps prevent redesigns that can delay timelines or increase expenses.

Key Fabrication Factors To Consider

Product dimensions and tolerance requirements serve as the inspiration for our design teams. While handling conditions influence how the shipping trays perform during movement and storage, the equipment compatibility ensures each unit works as intended on the line.

Each factor shapes whether the shipping tray supports your specific client or creates friction within the customer experience.

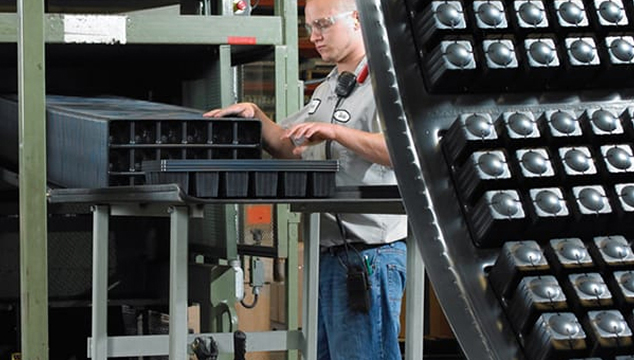

Collaborating With a Custom Plastics Manufacturer

An experienced plastics manufacturer should collaborate with pharmaceutical teams early in the development workflow to assess trade-offs before tooling decisions are made. Prototyping allows teams to confirm the fit and performance before locking in their tooling investments.

This approach supports scalable solutions that remain consistent and price-effective as demand increases.

Validation, Testing and Quality Assurance

Plastic solutions undergo testing based on customer requirements to confirm their durability and repeatability, with documentation that supports validation and regulatory requirements if the operation scales. This approach helps maintain consistent performance over time.

When Generic Solutions Fall Short: Signs You Need a Custom Approach

Standard solutions often struggle as products evolve or volumes increase. Repeated damage during handling or inefficiencies tied to manual adjustments signal a mismatch between the solution and real operational needs. These issues tend to surface gradually, then become harder to ignore as your scale increases.

Regulatory challenges can also emerge when generic solutions fail to deliver consistent performance. In regulated environments, inconsistency creates risk that extends beyond the floor and into audits and investigations.

Future Trends in Pharmaceutical Handling Solutions

Automation continues to reshape requirements across pharmaceutical operations. Thermoformed plastic solutions built for robotics and tracking technologies will play a larger role as systems become more connected.

Innovation will also influence future approaches, particularly for shipping solutions used at scale. These changes will continue to push companies toward purpose-built systems rather than one-size-fits-all options.

Why Custom Plastic Trays Are a Strategic Investment for Pharma

Purpose-built solutions protect product integrity while supporting efficient operations and compliance expectations. For pharmaceutical manufacturers, well-engineered plastic thermoformed solutions reduce risk and improve consistency across internal workflows and distribution channels.

As operations grow more complex, tailored solutions provide a reliable foundation. They shift protective systems from a constraint into a functional part of how the operation runs.

Talk with T.O. Plastics about purpose-built solutions for your pharmaceutical applications.

Connect with a specialist to discuss your requirements, performance needs, and scalable solutions for heavily regulated environments.