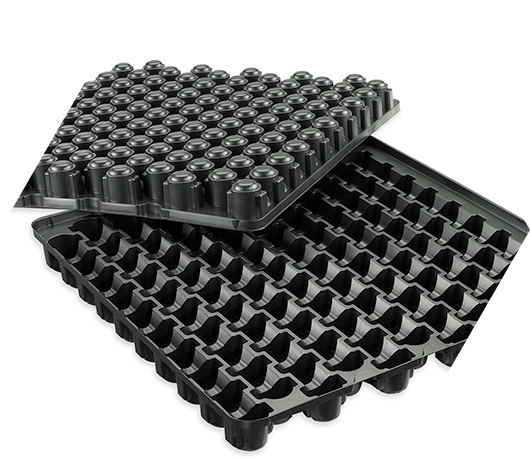

Thermoformed Plastic Products and Packaging

When it comes to producing industrial thermoformed products and packaging, T.O. Plastics has unparalleled experience in every step of the process, including design, research and development, thermoforming, and quality control. Our difference is we have capabilities and experience in heavy and thin gauge thermoforming. We're geared to take a plastic packaging, custom product, or enclosure project from concept and design, to tooling and manufacturing, no matter your requirements.