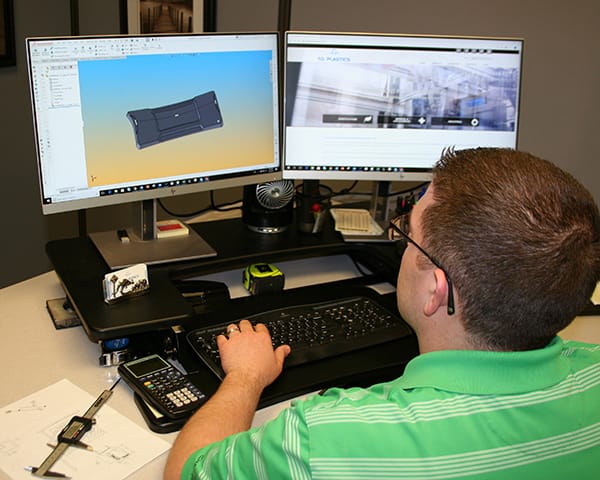

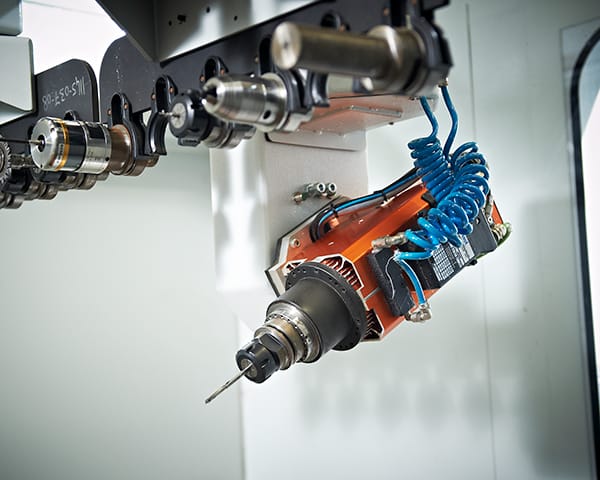

Our Process

Providing customers with custom thermoformed plastic packaging and parts is what we do, and our customer-centered process ensures we do it right. Our process guides customers from the early stages of discovering their concept, designing their vision, and building prototypes all the way through building a custom thermoforming tool and producing the packaging according to their specifications and value metrics. And throughout every step of the thermoforming process, our focus on customer care ensures top-notch quality, communication, and service.