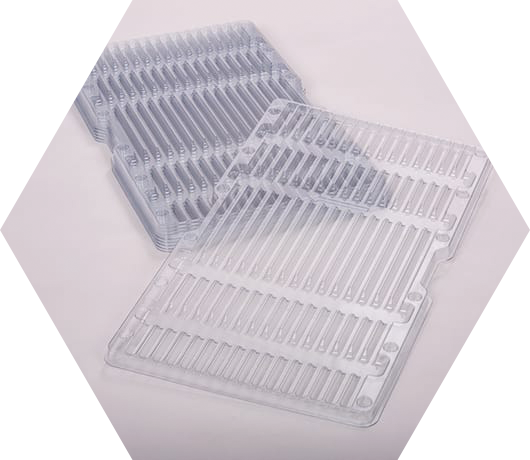

Thermoforming Medical Products

Backed by over 30 years of medical industry experience, T.O. Plastics has the expertise and knowledge to design and thermoform medical grade plastic into the custom application you require. Our medical device thermoforming solutions offer extensive advantages, including structural stability, nestability, cost efficiency, and weight efficiency. Our customers know they can rely on our product to protect their medical device components throughout all operations, including processing and transportation.

Our expertise extends over the full range of medical fields. We provide medical grade plastic solutions for the areas of cardiovascular, surgical, orthopedic, patient care, neurosurgery, medical supply, and monitoring. Plus, our medical device thermoforming is well-suited to standard sterilization processes. Our products are easy to handle and can be quickly sealed and pouched at your facility.