Who We Serve

Medical & Life Sciences

T.O. Plastics provides top-of-the-line medical device thermoforming with state-of-the-art certified Class 8 cleanrooms. No matter what type of packaging your medical device requires, T.O. Plastics will work to design the solution that will meet your requirements.

Who We Serve

Industrial

When it comes to producing industrial thermoformed products and packaging, T.O. Plastics has unparalleled experience in design, research and development, thermoforming, and quality control. Diversification is key, and T.O. Plastics has it.

Who We Serve

Recreational

T.O. Plastics provides high-quality thermoforming services for customers needing an array of recreational plastic products and enclosures. We thermoform plastic parts equipped to meet your needs for RV, ATV, UTV, and snowmobile parts and components.

Who We Serve

Electronic

We regularly work with customers in need of electronics packaging, including electronic trays and enclosures, and manufacture them with static dissipative, anti-static plastics, and conductive materials that are crucial in electronics component packaging applications.

Who We Serve

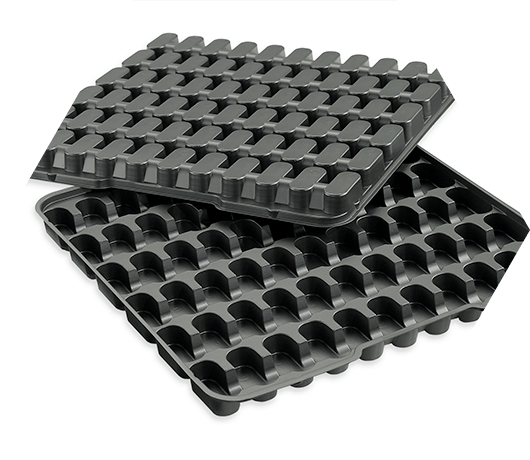

Horticulture

T.O. Plastics offers superior plastic plant trays and pots that improve the growing process. Within the horticulture market, we are recognized as plug tray experts and efficiency innovators with time-tested strategies for optimizing timelines and reducing labor costs.

Who We Serve

Agriculture

T.O. Plastics provides high-quality thermoforming services for customers needing an array of agricultural plastic products and enclosures. We thermoform plastic parts equipped to meet your needs for agriculture parts and components.

Who We Serve

Consumer Packaging

We work with customers in need of consumer packaging, including blister packaging, clamshell packaging, and tri-fold clamshells. We can manufacture an endless variety of durable plastic products and packaging options for consumer goods.

Who We Serve

Roll Stock

We extrude a variety of plastic substrates, including the utility grade and prime HIPS and ABS roll stock, and we offer it in truckload quantities. Our roll stock comes in a variety of gauges, colors, and volumes.

Custom Thermoforming from Concept to Production

01 / Discover

This first step in our process is all about discovering what our customer needs and outlining their requirements. It includes conversations with sales staff to determine needs, volume metrics, and any known requirements relevant to design, quality, and timeline.

02 / Design

During design, our in-house engineering teams begin creating concepts and drafting the drawing according to customer specifications. Recommendations on material type, color, and gauge will be determined based on the qualities and properties the final product needs to have.

03 / Prototype

Next, we take the approved design and create a proto-mold to produce samples. These samples are used to validate the specifications defined during the design stage. We’re able to evaluate the functionality of the features of the design, along with the material type and gauge.

04 / Tool

It’s time to build the production tool. As our in-house engineering team begins the tool building process, they’ll provide a timeline for completion. At this time, first article approval is signed off by both parties and production scheduling begins.

05 / Produce

Upon receipt of the custom order, it's time to produce. This includes developing a master control plan, which enables us to get materials in order and schedule production time into our current workflow. During the first part run, we verify our quality check procedure. The customer knows what date they can expect their product, so they can align their processes accordingly.

06 / Customer Care

During every step of our process, customer care is present. Whether customers are interacting with sales reps, design engineers, or customer service staff, we lead with a focus on the customer experience. At T.O. Plastics, we focus on customer-centered design, and we’ve refined our process to reflect that reality.

Some Things Do Age Well

Here at T.O. Plastics, we’re not new to the scene. In fact, we’ve been designing, developing, and producing custom thermoformed plastic trays for use in numerous industries for over 75 years. During that time, we’ve grown and evolved within our industry and developed an unmatched level of expertise in our services and capabilities.

We are committed to providing custom and proprietary solutions for the medical, industrial, horticulture, recreational, electronic, agriculture, consumer packaging, and roll stock, and we do so by utilizing our engineering, design, tooling, and innovative manufacturing capabilities.