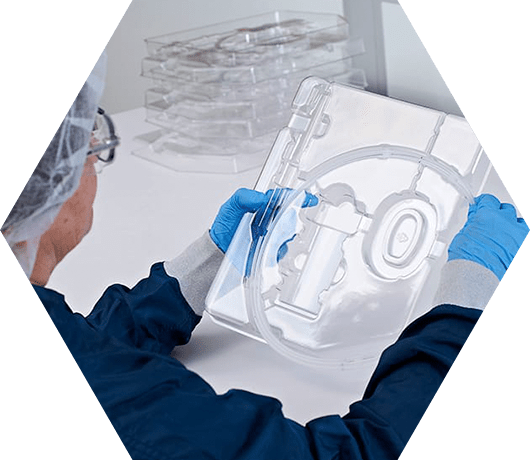

Plastic Manufacturing Capabilities

T.O. Plastics helps customers overcome some of their biggest thermoforming challenges. As a custom thermoforming company specializing in thin and heavy gauge plastic solutions with experienced staff, specialized equipment, and a wide variety of secondary operations and routing capabilities, we can offer services such as line bending, assembly/bonding, and high-speed, self-feed trimming. At T.O. Plastics, we are always on a quest for continuous improvement. To help reduce our cycle times, we upgraded to a 5-Axis CNC router. This means we can handle parts with the most exacting trim requirements.